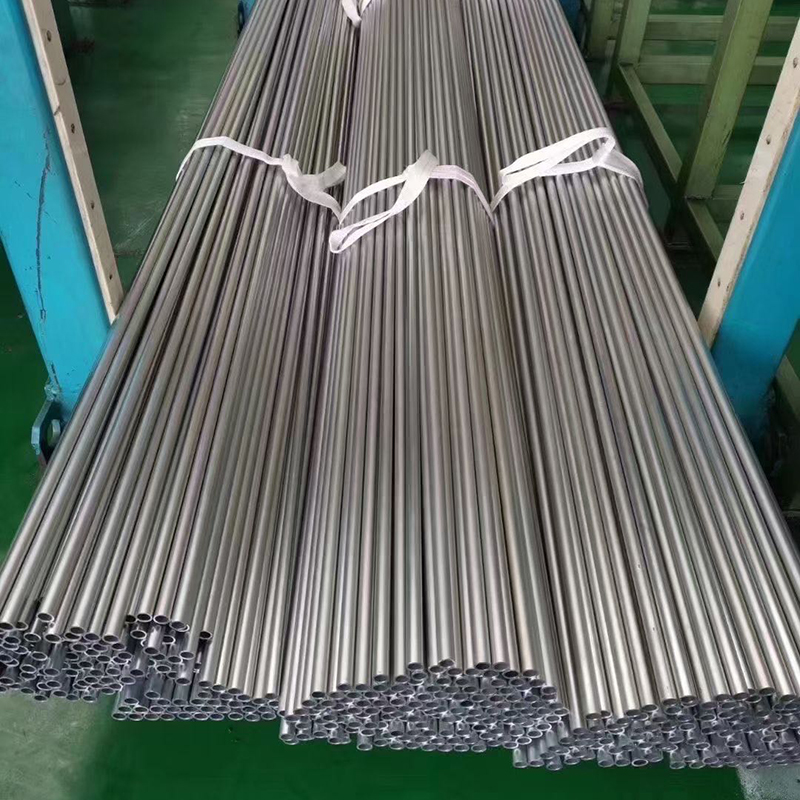

JIS G3445 STKM11A STKM12B STKM13B Tiwb Dur Di-dor

Nodweddion

Gradd Deunydd:

STKM 11A 12A 12B 12C 13A 13B 13C 14A 14B 14C 15A 15C etc.

Triniaeth arwyneb:

1.Bared

2.Black Painted (cotio farnais)

3.Galfanedig

4.Oiled

5.According i gwsmeriaid.

Defnyddir tiwbiau dur manwl JIS G3445 yn bennaf mewn rhannau modurol a pheiriannau manwl ar gyfer ceir a silindr.defnydd pwysau, a hefyd ar gyfer cludo stêm, dŵr, llinellau pibellau nwy.

Cyfansoddiad cemegol

| Gradd | Dynodiad | Uned (%) | ||||||

| C | Si | Mn | P | S | Nb neu V | |||

| Gradd 11 | A | STKM 11A | 0.12 uchafswm. | 0.35 uchafswm. | 0.60 uchafswm. | 0.040 uchafswm | 0.040 uchafswm | - |

| Gradd 12 | A | STKM 12A | 0.20 uchafswm. | 0.35 uchafswm. | 0.6 uchafswm. | 0.04 uchafswm. | 0.04 uchafswm. | |

| B | STKM 12B | |||||||

| C | STKM 12C | |||||||

| Gradd 13 | A | STKM 13A | 0.25 uchafswm. | 0.35 uchafswm. | 0.30 ~ 0.90 | 0.040 uchafswm | 0.040 uchafswm | - |

| B | STKM 13B | |||||||

| C | STKM 13C | |||||||

| Gradd 14 | A | STKM 14A | 0.30 uchafswm. | 0.35 uchafswm. | 0.30 ~ 1.00 | 0.040 uchafswm | 0.040 uchafswm | - |

| B | STKM 14B | |||||||

| C | STKM 14C | |||||||

| Gradd 15 | A | STKM 15A | 0.25 ~ 0.35 | 0.35 uchafswm. | 0.30 ~ 1.00 | 0.040 uchafswm | 0.040 uchafswm | - |

| C | STKM 15C | |||||||

| Gradd 16 | A | STKM 16A | 0.35~0.45 | 0.40 uchafswm. | 0.40 ~ 1.00 | 0.040 uchafswm | 0.040 uchafswm | - |

| C | STKM 16C | |||||||

| Gradd 17 | A | STKM 17A | 0.45~0.55 | 0.40 uchafswm. | 0.40 ~ 1.00 | 0.040 uchafswm | 0.040 uchafswm | - |

| C | STKM 17C | |||||||

| Gradd 18 | A | STKM 18A | 0.18 ar y mwyaf. | 0.55 uchafswm. | 1.50 uchafswm. | 0.040 uchafswm | 0.040 uchafswm | - |

| B | STKM 18B | |||||||

| C | STKM 18C | |||||||

| Gradd 19 | A | STKM 19A | 0.25 uchafswm. | 0.55 uchafswm. | 1.50 uchafswm. | 0.040 uchafswm | 0.040 uchafswm | - |

| C | STKM 19C | |||||||

| Gradd 20 | A | STKM 20A | 0.25 uchafswm. | 0.55 uchafswm. | 1.60 uchafswm. | 0.040 uchafswm | 0.040 uchafswm | 0.15 uchafswm |

Priodweddau mecanyddol

| Gradd Dur | Cryfder Cynnyrch (Mpa) | Cryfder Tynnol (Mpa) | Elongation (%) | |

| Enw | Nac ydw. | ReH (munud) | Rm(mun) | A(munud) |

| STKM 11A |

| _ | 290 | 35 |

| STKM 12A |

| 175 | 340 | 35 |

| STKM 12B |

| 275 | 390 | 25 |

| STKM 12C |

| 355 | 4700 | 20 |

| STKM13A |

| 215 | 370 | 30 |

| STKM 11B |

| 305 | 440 | 20 |

| STKM11C |

| 380 | 510 | 15 |

Goddefgarwch

| MAINT | Goddefgarwch a ganiateir | Goddefgarwch Arbennig | ||

| OD | WT | OD | WT | |

| 4mm-20mm | ±0.25mm | <3mm±0.3mm;

≥3mm ±10%

| ±0.05mm | ±0.05mm |

| 20mm-30mm | ±0.25mm | ±0.08mm | ±0.08mm | |

| 31mm-40mm | ±0.25mm | ±0.10mm | ±0.08mm | |

| 41mm-49mm | ±0.25mm | ±0.15mm | ±0.15mm | |

| 50mm-80mm | ±0.5% | ±0.20mm | ±0.20mm | |

| 81mm-120mm | ±0.5% | ±0.30mm | ±0.30mm | |

Amod danfon

| Dynodiad | Symbol | Disgrifiad |

| Wedi gorffen yn oer (caled) | BK(+C) | Nid yw tiwbiau'n cael triniaeth wres ar ôl y ffurfiant oer terfynol ac, felly, mae ganddynt wrthwynebiad eithaf uchel i anffurfiad |

| Wedi gorffen yn oer (Meddal) | BKW | Dilynir y driniaeth wres derfynol gan luniad oer sy'n cynnwys anffurfiad cyfyngedig.Mae prosesu pellach priodol yn caniatáu rhywfaint o ffurfio oer (ee plygu, ehangu) |

| (+LC) | ||

| Wedi gorffen yn oer ac yn lleddfu straen | BKS(+SR) | Rhoddir triniaeth wres ar ôl y broses ffurfio oer ddiwethaf.Yn amodol ar amodau prosesu priodol, mae'r cynnydd yn y straen gweddilliol dan sylw yn galluogi ffurfio a pheiriannu i raddau. |

| Annealed | GBK(+A) | Mae'r broses ffurfio oer olaf yn cael ei dilyn gan anelio mewn awyrgylch rheoledig. |

| Wedi'i normaleiddio | NBK(+N) | Dilynir y broses ffurfio oer olaf gan anelio uwchben y pwynt trawsnewid uchaf mewn awyrgylch rheoledig. |

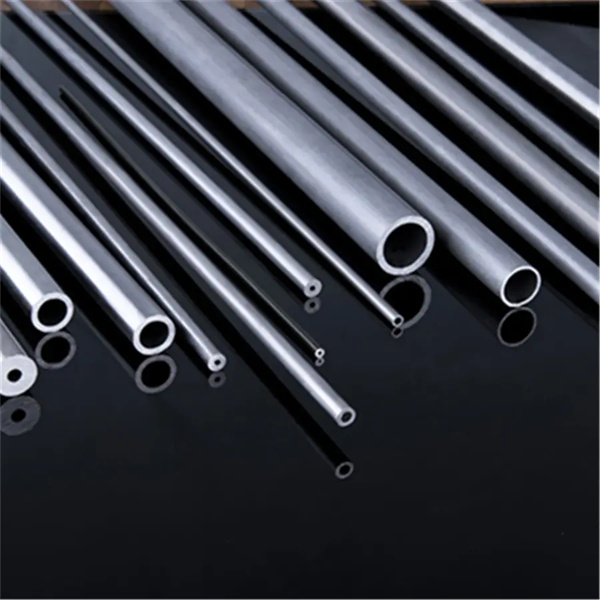

| Tiwbiau Dur Precision Uchel mewn Stoc | ||||||||||

| OD | Trwch(mm) | |||||||||

| mm | ||||||||||

| 4 | 4*1 | |||||||||

| 6 | 6*1 | 6*1.5 | 6*2 | |||||||

| 8 | 8*1 | 8*1.5 | 8*2 | |||||||

| 10 | 10*1 | 10*1.5 | 10*2 | 10*2.5 | ||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | 12*3 | |||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | |||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | 15*3.5 | ||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | 16*3.5 | 16*4 | 16*4.5 | ||

| 18 | 18*1 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | 18*4.5 | ||

| 20 | 20*1 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | 20*4.5 | 20*5 | |

| 22 | 22*1 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | 22*4.5 | 22*5 | |

| 25 | 25*1 | 25*1.5 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | 25*4.5 | 25*5 | |

| 28 | 28*1 | 28*1.5 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | 28*4.5 | 28*5 | |

| 30 | 30*1 | 30*1.5 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | 30*6 |

| 32 | 32*1.5 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | 32*6 | |

| 34 | 34*1.5 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |

| 35 | 35*1.5 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | ||

| 40 | 40*2 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||

| 42 | 42*2 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||

| 45 | 45*2 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||

| 46 | 46*2 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||

| 48 | 48*2 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||

| 50 | 50*2 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||

| 54 | 54*2.5 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||

| 60 | 60*2.5 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | |||

| 65 | 65*3 | 65*3.5 | 65*4 | 65*4.5 | 65*5 | 65*6 | ||||

| 75 | 75*3.5 | 75*4 | 75*4.5 | 75*5 | 75*6 | |||||

| 76 | 76*4 | 76*4.5 | 76*5 | 76*6 | ||||||

| 89 | 89*6 | |||||||||

| Nodyn: Gallem gynhyrchu meintiau eraill fel eich gofynion.Triniaeth Arwyneb: Disglair, Galfanedig, Ffosffad ac ati. | ||||||||||

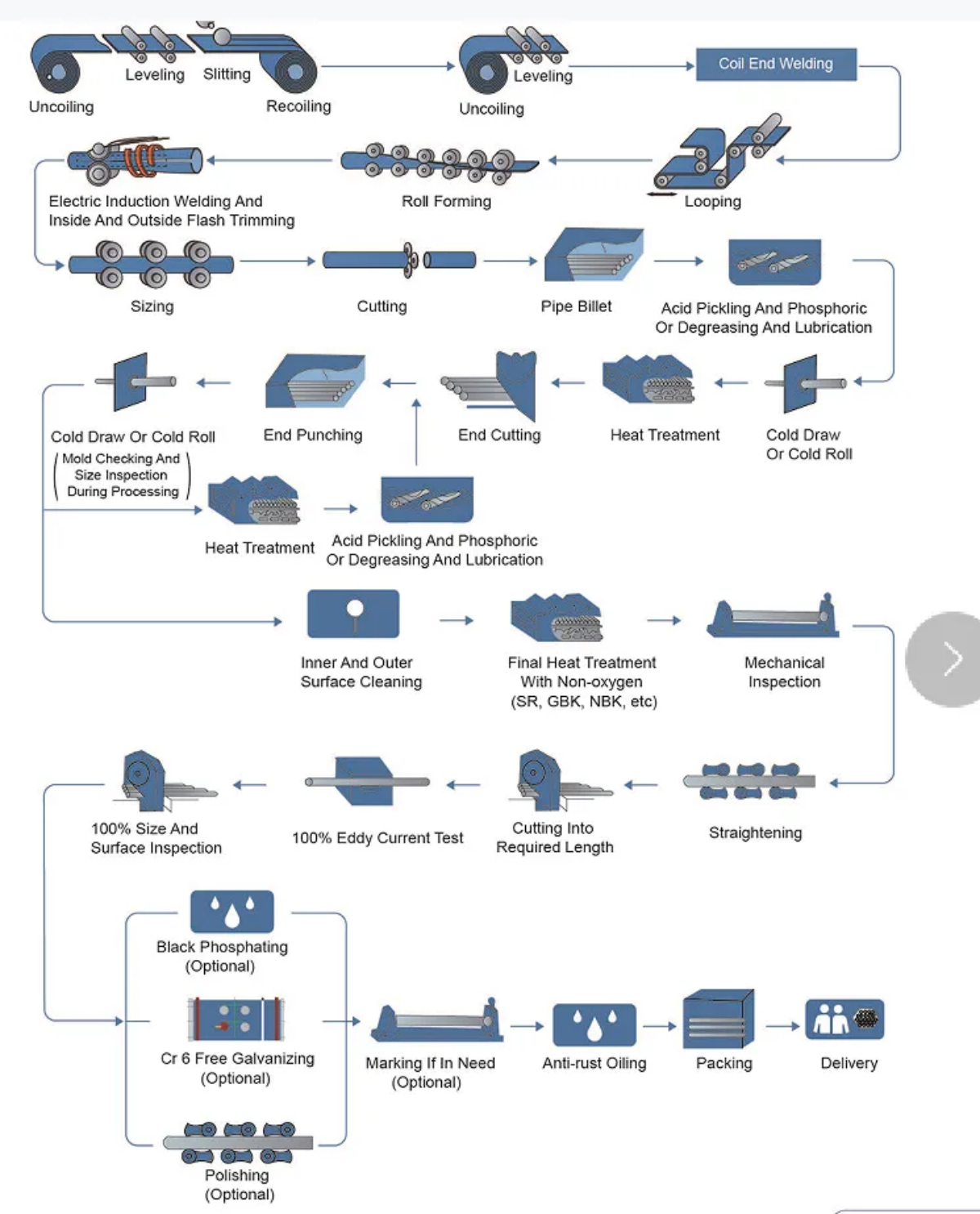

Proses Gweithgynhyrchu

Manteision

Cryfhau arolygu cynhyrchion ym mhob cam cynhyrchu, gyda chyfarpar profi cyflawn: profion cerrynt eddy annistrywiol, peiriant profi ymwrthedd pwysedd uchel, peiriant profi tynnol mecanyddol cyffredinol, peiriant profi fflerau gwastadu plygu, dadansoddwr glendid, dadansoddwr elfennau metel, ac ati. Cwrdd â phriodweddau mecanyddol cynhyrchion, prawf perfformiad proses, darparu gwarant pwerus ar gyfer cynhyrchion cymwys.

Sicrwydd ansawdd

1. Yn llym yn unol â Safon JIS G3445 neu safonau eraill.

2. Sampl: Sampl yn rhad ac am ddim ar gyfer prawf.

3. Profion: Prawf chwistrellu halen / Prawf tynnol / cerrynt Eddy / Prawf cyfansoddiad cemegol yn unol â chais cwsmeriaid

4.Certificate: IATF16949, ISO9001, SGS ac ati.

5.EN 10204 3.1 Ardystiad